Sugar... The Silent Killer! - The Risks To Food Automation

What Sugar Does do to your Equipment?

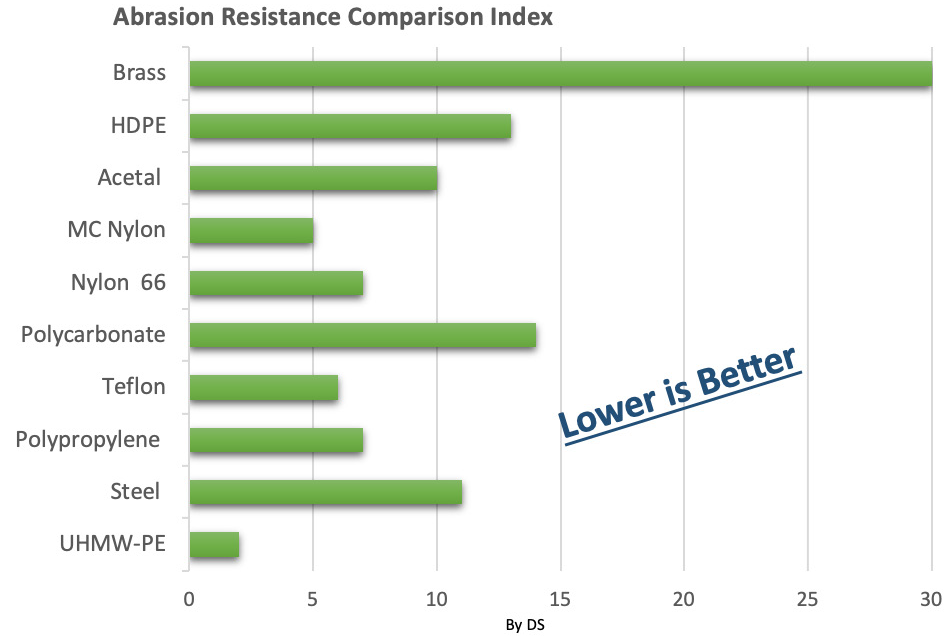

Everyone enjoys a sweet treat, but too much can lead to health issues. Well, sugar is also a silent killer with respect to Food Processing Equipment. Sugar is inherently sticky and is naturally abrasive. The combination of these two properties is severely problematic for processing of confectionary foods. Sugar’s abrasiveness significantly reduces the life of wear components within any type of automation. So how does this affect the choice of plastics?

The Cause: Abrasive Wear

Defined as the volume of material loss caused by abrasive media moving through or over a component. Abrasive wear isn’t just related to sugar other abrasive media such as flour, grains, nuts, and coffee will also cause premature surface wear.

The Solution

Ultra High Molecular Weight Polyethylene (UHMW-PE) is polymer with an extreme resistance to sliding abrasion or slurry abrasion. It is the most commonly used material in critical food processing applications with a focus on abrasive wear resistance. In addition UHMW-PE has low friction, high abrasive resistance, good toughness, high impact strength, high resistance to corrosive chemicals, no moisture absorption, and low cost.

However, not all UHMW-PE are equal in performance. There are two major influences that will determine the performance of UHMW-PE components within Food Processing Equipment.

Molecular Weight

UHMW-PE has a molecular range between 3M – 6M depending on manufacture. Molecular weight influences the performance in terms of wear, izod impact as well as static and dynamic friction.

Fillers

Stock shape manufacturers use a variety of fillers to enhance a particular property. For example, glass might be added to improve stiffness and compressive strength, reduce expansion, and increase operating temperature. Glass does negatively impact Coefficient of Friction and can be abrasive to metals such as Stainless, Aluminum and brass often found within food processing equipment.